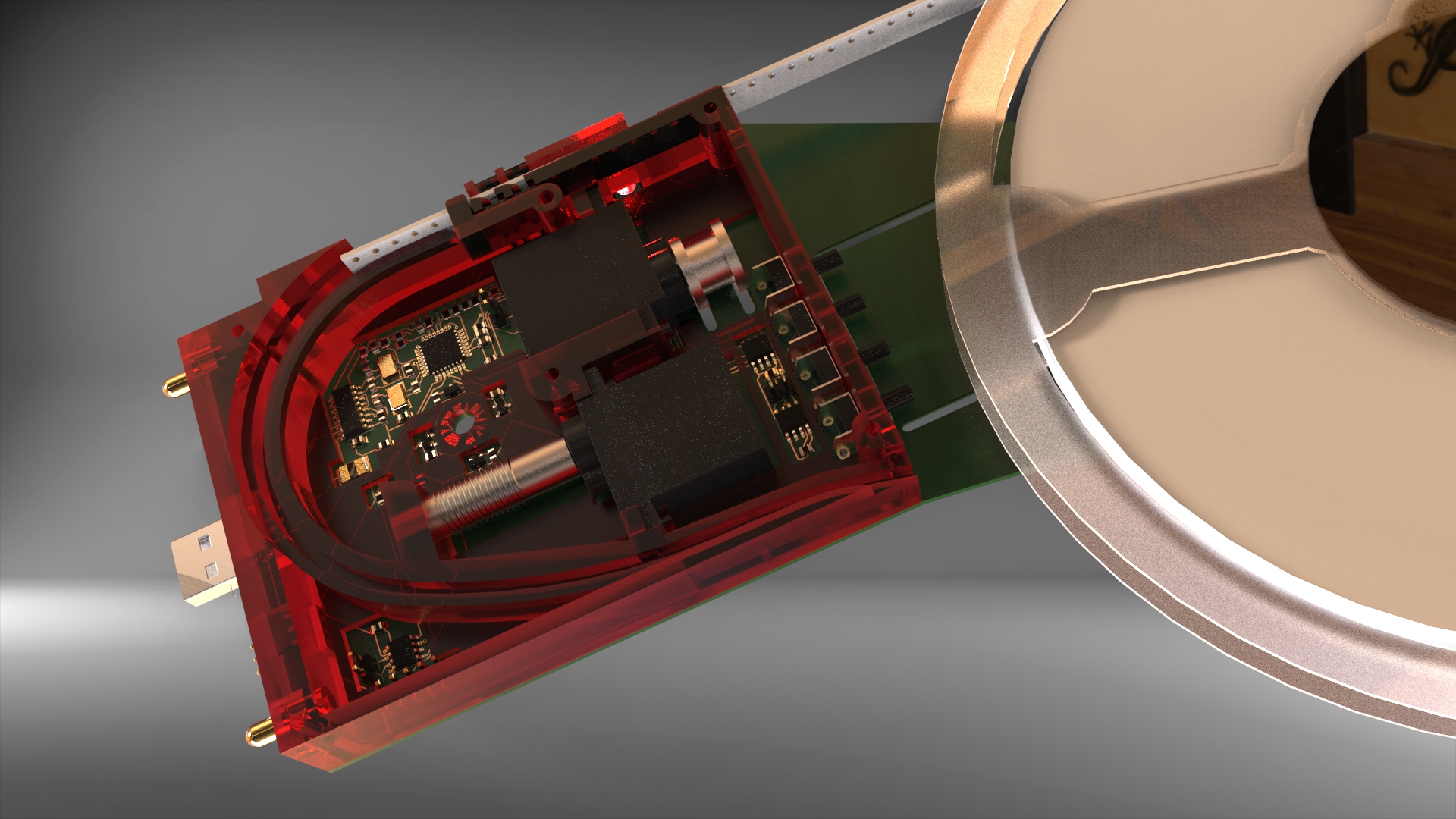

Hardware prototyping:

Our Hardware Prototyping service at Innonium is a pivotal step in transforming your innovative ideas into tangible reality. We specialize in creating functional and sophisticated hardware prototypes that serve as a pivotal bridge between conceptualization and final product development.

Key Features:

- Conceptualization to Reality: We take your initial concepts and transform them into functional hardware prototypes, providing you with a physical representation of your product vision.

- Precise Replication: Our skilled engineers meticulously replicate your design specifications, ensuring that the hardware prototype closely resembles the intended final product.

- Rapid Iteration: Our rapid prototyping approach allows for quick iterations and modifications, enabling you to refine your hardware design efficiently.

- Materials and Components: We use high-quality materials and components that align with your product’s requirements, enhancing the prototype’s accuracy and functionality.

- Functional Testing: Each hardware prototype undergoes rigorous testing to verify its performance, functionality, and adherence to design specifications.

- Proof of Concept: Our prototypes serve as a proof of concept, allowing you to demonstrate the feasibility and viability of your hardware idea to stakeholders and investors.

- Design Validation: Hardware prototyping validates your design assumptions, providing valuable insights before moving forward with full-scale manufacturing.

Benefits:

- Visualize Your Vision: Hardware prototypes provide a tangible representation of your idea, making it easier for you and stakeholders to visualize the end product.

- Effective Communication: Prototypes facilitate better communication about your hardware design, helping bridge the understanding gap between designers, engineers, and stakeholders.

- Iterative Refinement: Rapid iterations based on prototype testing and user feedback enable you to refine and enhance your hardware design efficiently.

- Risk Reduction: Identifying and addressing design flaws or functionality issues at the prototype stage minimizes risks associated with full-scale production.

- Investor Engagement: Hardware prototypes impress investors by demonstrating the potential of your product, increasing your chances of securing funding.

- Time and Cost Savings: Addressing design concerns early in the prototyping phase prevents costly modifications during later stages of development.

- Market Validation: Presenting a functional hardware prototype to potential users allows you to gather feedback and validate your product idea before full-scale production.

At Innonium, our Hardware Prototyping service empowers you to take a confident step forward in your product development journey. Whether you’re refining an existing product or innovating a groundbreaking concept, our prototypes offer the hands-on experience you need to achieve success. Partner with us to witness your hardware vision transform into a tangible reality.

Learn more about: